检测到您正在使用中文浏览器访问

您当前访问的是英文版网站。

为获得更好的本地化体验,建议您切换到中文版。

Business Challenges

Huge Safety Hazards

Mining trucks are large with many blind spots, posing collision or crushing risks.

High personnel operation intensity, lack of rescue facilities, and frequent safety accidents.

Shortage of Practitioners

Located in remote areas, with much dust, loud noise, and harsh environment.

Aging of skilled workers, frequent personnel turnover, and interruption of technical inheritance.

High Operating Costs

High Operating Costs

Non-standard operation leads to high fuel consumption, high loss, and increased operating expenses.

Efficiency Bottleneck

Multiple shifts per day, frequent shift handovers reduce working hours.

Lack of scheduling in manual driving, queuing and waiting affect comprehensive efficiency.

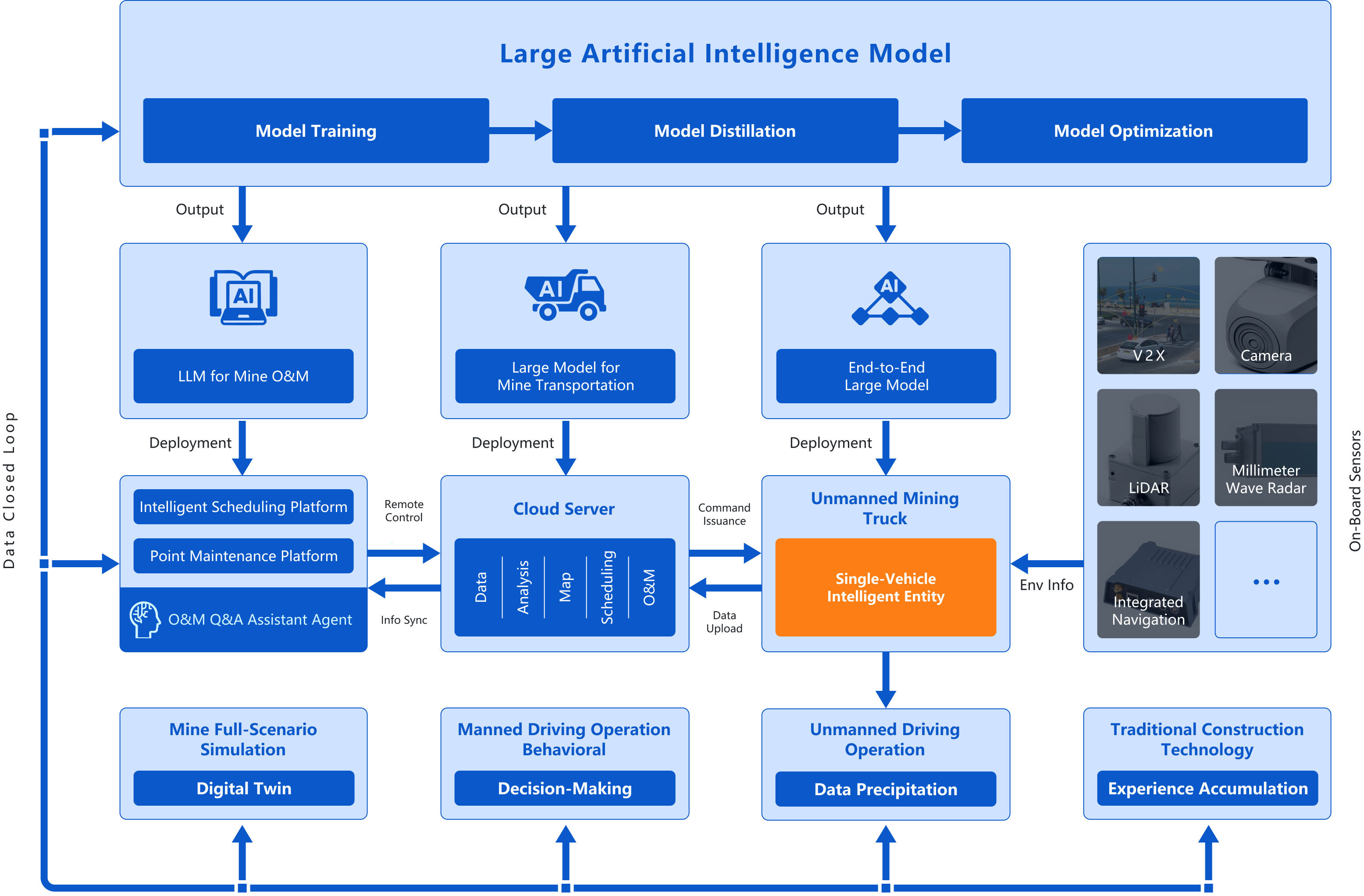

Solution Architecture

Advantages of the plan

More Efficient

24-hour uninterrupted operation

Efficiency can be as high as 95% of manual work.

More Economical

Reduce labor and fuel expenses.

Comprehensively reduce transportation costs by more than 30%.

Safer

Recognizes and avoids general obstacles from 30 meters away

Distinguishes objects 10 cm high.

Clearer

Based on map crowdsourcing update

Based on map crowdsourcing update

More Reliable

Operable when visibility is less than 30 meters

Unaffected by extreme weather like sandstorms, rain, and snow.

Smarter

Rare strong single-vehicle intelligence in the industry

Capable of offline autonomous operation for 4-5 hours.

More Accurate

Turning radius less than 13 meters

Braking distance reduced by 30%.

Lighter

72-hour rapid solution deployment

No need to build additional roadside units.

Vehicle grade sensor configuration